Statics

In general, you can rely on the statics of house construction and accommodate special features such as grand pianos or soundproof cabins in your building without any problems. Nevertheless, the weight load on the ceiling must sometimes be checked.

The subject has a few myths. As a correct source of information, please refer to the relevant DIN standard 1055-3. Quick calculations and estimates by non-experts often lead to incorrect results. If in doubt, consult a structural engineer.

The engineer will determine the respective individual load separately and combine it with the evenly distributed payload.

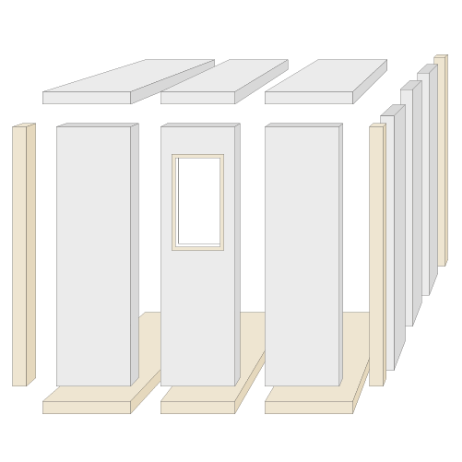

How is my soundproof booth made?

From our experience

In almost 30 years of STUDIOBOX, we are not aware of a single case where the load-bearing capacity test did not result in an "OK".

The weight of the cabin is not - as is often assumed - distributed one-to-one (1:1) over the floor space of the cabin, but over the entire surface of the ceiling. This means that the load per square metre is considerably lower. The 1 : 1 calculation, on the other hand, leads to incorrect assumptions.

However, please note that we are not authorised to make binding statements about the construction quality of your house.